Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 122

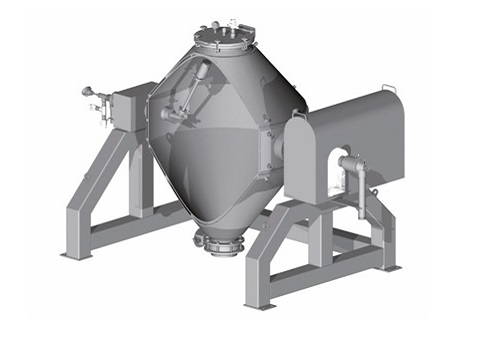

Double cone Blender

Double Cone Blenders are most often used for dry blending of free flowing solids. The solids being blended in these units can vary in bulk density and in percentage of the total mixture. Materials being blended are constantly being intermixed as the Double Cone rotates.

The double cone blender consists of two conical sections joined together at their bases to a central cylindrical section. The axis of rotation is perpendicular to the cone axis and passes through the cylindrical section. Charging of material into the double cone blender is through one of the conical ends whereas the discharge is through the opposite end. As the blender rotates about the central axis, the powder inside the blender alternately flows together when a conical end is down, and flows apart when the ends are horizontal.

Double Cone Blenders are designed to perform blending operations for mixing dry powder and granules homogeneously with precision. Double Cone Blenders are often used for the intimate dry blending of free flowing solids.

- DOWNLOADS

- ENQUIRE NOW

Working Principle

The main body of the blender consists of two cone-shaped sections welded at their bases to a central cylindrical section. The axis of rotation is perpendicular to the cone axis and passes through the cylindrical section. The driving motor is located at one of the two lateral supports holding the blender body. The solids are introduced into the blender through the loading aperture. In this blender, mixing takes place axially, as a result of the powder moving through the different sections.

Applications

Dry Powder to powder mixing for tablets and capsules formulations.

Dry granules sub lots mixing to increase the batch size of bulk lubrication stage of tablet granules.

Dry powder to wet mixing