Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 122

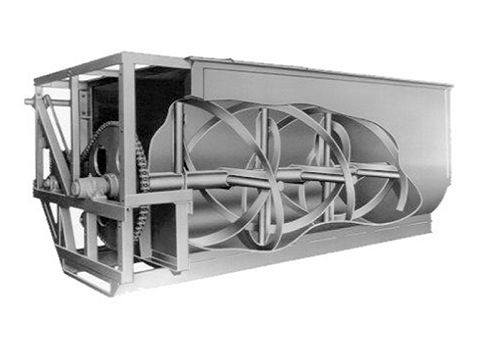

Ribbon Blender

Ribbon Blender consists of transmission parts, double ribbon agitators and U-shape trough. In the direction of rotation, the outer ribbon pushes materials from both ends to the middle, while the inner ribbon pushes materials from the middle to both ends. The particles move in a helical fashion upward and flows down centrally. Ribbon wind with different angle direction carries the materials flowing in different directions. Through continuous convective circulation, the materials are sheared and mixed thoroughly and quickly. Ribbon Blenders are primarily designed for use with dry materials, although gas and liquid streams can also be added. A wide variety of configurations, for either batch or continuous mixing, are available with different sizes

- DOWNLOADS

- ENQUIRE NOW

Working Principle

The Ribbon Blender consists of a drive assembly, a double layer ribbon shaped agitator and a u-shaped trough. Inner Ribbons move the materials towards the ends of the ribbon blender whereas the outside ribbons move the material back towards center of the ribbon blender, therefore, materials are mixed efficiently. The direction of material flow is determined by ribbon angle, direction and twining method. The outlet for material is located centrally at bottom of the blender. Outside ribbon driven by main shaft moves the material towards discharge port ensuring no dead zones inside the blender.

Applications

The ribbon blender is used for multiple blending applications due to its versatility for blending solids combined with its ability to perform heating, cooling, coating and other processes.

Capacities

50 liters to 3500 liters