Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 122

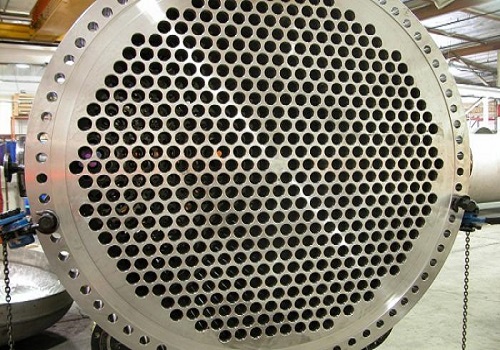

Shell & Tube Heat Exchangers

Shell and Tube heat exchangers are most commonly used in heating or cooling process fluids and gases. Typically found in applications where a need to heat or cool large volumes exist; however small volume applications are also very common. As a result of their design, shell tube heat exchangers offer a large surface area and thus high heat transfer efficiency. Shell and tube exchangers come in many variations to meet process requirements in almost every industry or application. They deliver reliable heat transfer performance by utilizing a high turbulence and counter flow, making one or more passes. While one (1), two (2) and four (4) pass models are standard, multi-pass custom models can be built to suit the customers' requirement.

- DOWNLOADS

- ENQUIRE NOW

Working Principle

Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side). Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. The fluids can be either liquids or gases on either the shell or the tube side. In order to transfer heat efficiently, a large heat transfer area should be used, so there are many tubes. In this way, waste heat can be put to use. This is a great way to conserve energy.